crucial role of industrial pumps

Waste water treatment

Wastewater treatment is an important process for protecting our environment and maintaining clean water. Waste water is produced in many industrial processes and it is very important to treat it responsibly. This is where industrial pumps come into the picture.

Industrial pumps play an important role in wastewater treatment. They are used to transport and filter the waste water. This means that the cleaner water can be returned to nature or reused in the production process.

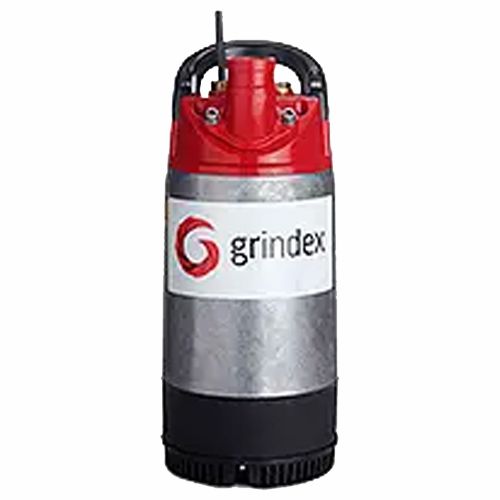

GRINDEX series

See below some of the series of GRINDEX pumps available in our webshop

Grindex Micro

Small submersible pump suitable for contaminated liquids

Grindex Mini

Submersible pump suitable for contaminated liquids

Grindex Minor N/H

Submersible pump with free passage for solids up to 10 mm

Grindex Matador N/H

Submersible pump with double mechanical seal in oil bath SiC/SiC-Tun/Tun

Grindex Master N/H/SH

Submersible pump suitable for contaminated liquids

Grindex Magnum N/H/L

Submersible pump with a capacity of up to 1260 m3/h

Grindex Solid

Submersible pump with free solids passage of up to 38 mm

Grindex Sandy N/H

Submersible pump for contaminated liquids with max. temperature of 40°C

Grindex Senior

Suitable for contaminated liquids and with free passage of solids up to 80 mm

Grindex Bravo serie N/H

Submersible pump for contaminated liquids and slurry

Is your Grindex pump not listed here?

Our pump experts will be happy to help you find/deliver your required pump or parts

About Grindex

Grindex is a world leader in the technology of electric submersible pumps for demanding applications such as construction, mining and heavy industry. Since 1960, Grindex has been fully committed to developing the highest quality electric submersible pumps, designed without compromise for professional users worldwide. The range includes pumps for every need: drainage, sludge and slurry, suitable for the most challenging environments.

Grindex is committed to the highest quality standards and is certified to the ISO 9001 quality standard. This certification ensures that all processes, from design to production and testing, are carried out under controlled quality conditions for every pump we make. Grindex has been certified since February 1996 and has met this standard ever since.

PARTS AND MAINTENANCE

No matter how wear-resistant a pump is, no pump escapes overhaul. For both individual parts and a complete overhaul, Industrial Pump Group Nederland is the right place for you. As an official dealer and with a strong relationship with the supplier, we can help you get spare parts or overhaul your pump.

WHY CHOOSE GRINDEX PUMPS?

Grindex pumps are made from the most wear-resistant materials, for a longer life. The pump includes a fitted air valve and electronic protection that allows it to run dry. Unlike standard submersible pumps, these pumps feature a vortex impeller and a larger pump housing for greater free passage. This makes the Grindex pumps ideal for demanding applications where reliability and continuous operation are essential.

Industrial Pump Group

Contact us

Vacancy

All-round pump mechanic

Job description

No, you won't always come home clean at this job as a pump mechanic. You will occasionally get your hands dirty and sometimes stand with your feet in mud. You will be tinkering with pumping stations and associated pumping equipment, so you will need an occasional shower after work. Not put off? Good, because with this job you do have broad technical challenges. Mechanical spanner work, where your knowledge of pumps will be enhanced. That will certainly please you as a (starting) technician. Sometimes you will go out together with a colleague or alone, but mostly you will work from the workshop. You will be engaged in maintenance and overhaul of pumps.

Does this job appeal to you?

Then contact Robert de Brouwer on 0251-222566.

Or send your application using the form below.

Job requirements

Job requirements

We are looking for a pump mechanic with a mechanical, mechanical or electrical engineering background. You have a feel for technology: what your eyes see, your hands make and you easily pick up new work. Furthermore, you are quality-oriented, amicable, flexible and customer-oriented. Your working day starts at 7:30 a.m. but your finishing time sometimes depends on when the work is finished. Overtime is sometimes part of the job, but of course you will be home on time if necessary. You have a completed VMBO or MBO education in the field of engineering, in possession of a VCA diploma and driving license B.

Employment conditions

At this family business, the principle is that one good turn deserves another. A positive working atmosphere in which you can learn a lot and are offered the necessary certificates. Growth to an independent position as a (service) technician The benefits are excellent Does this wonderful job as a technician sound like your cup of tea? Then apply immediately!

learn more about wastewater

Various wastewater processes

Pre-treatment is the process of preparing the waste water for further treatment. The contaminants are removed and the wastewater is prepared for filtration. Different types of industrial pumps can be used in this process, depending on the specific requirements and challenges of the wastewater treatment process.

Closure is the process of discharging the treated wastewater. This ensures that the waste water does not flow back into the environment and that it is disposed of in a responsible manner. Industrial pumps play an important role in transporting the treated wastewater to the right location for disposal.

In addition to its role in wastewater treatment, industrial pumps can also be used in other applications, such as water treatment and water distribution. This makes it important to invest in high-quality industrial pumps in order to guarantee efficient and responsible water processing.