American Petroleum Institute

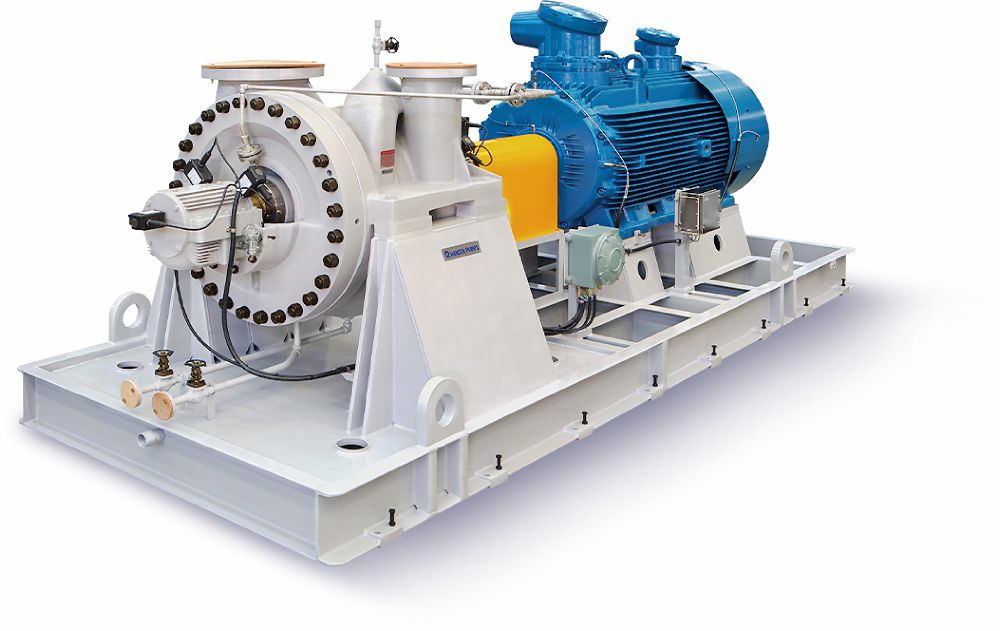

API 610 Pumps

API 610 pumps, manufactured to the rigorous standards of the American Petroleum Institute, are globally renowned for their outstanding performance. They play a vital role in various industries, effortlessly transferring fluids such as oil, gas, and chemicals. Their superior quality renders them indispensable in the realm of fluid displacement.

What truly sets API 610 pumps apart is their precision and reliability. API 610 is a specific standard for centrifugal pumps in the oil and gas industry. This standard imposes stringent requirements on design, materials, and manufacturing, resulting in pumps that excel in stability and durability, even in the harshest conditions. In contrast to other API pumps, API 610 pumps are meticulously engineered to cater to the intricate demands of the energy and oil sectors, where errors can have catastrophic consequences. Explore in this article why API 610 pumps are an indispensable choice for critical applications worldwide.

API 610 Specifications: A Comprehensive Analysis

API 610, also known as the American Petroleum Institute Standard 610, is a set of rigorous specifications that focus on centrifugal pumps used in the petrochemical, oil, and gas industries. This standard is crucial as it establishes the highest standards for design, manufacturing, and performance to ensure the reliability and safety of pumps in critical applications. Here, we take an in-depth look at what the API 610 specifications entail.

1. Categories of API 610 Pumps

API 610 pumps are categorized into various types, such as OH (overhung), BB (between-bearing), VS (vertical barrel), and VS6 (vertical can-type pump). Each category has specific design and performance requirements tailored to their intended applications. For instance, OH pumps feature an overhung shaft and are suitable for lighter-duty applications, while BB pumps are used for heavier tasks with higher pressures and capacities.

2. Materials and Fabrication

API 610 imposes strict requirements on the materials used in pump manufacturing. These materials must withstand the aggressive chemical environments often encountered in the petrochemical industry. The standard also mandates precise manufacturing methods to ensure quality and reliability.

3. Hydraulic Design

API 610 specifies requirements for the hydraulic design of pumps, including efficiency, Net Positive Suction Head (NPSH) behavior, and capacity. These specifications ensure that pumps perform optimally under various operating conditions and meet industry needs.

4. Mechanical Seals

Mechanical seals are vital to the integrity of pumps in the petrochemical sector. API 610 outlines requirements for mechanical seals, including type, lifespan, and performance criteria, to prevent leakage and ensure safety.

5. Test Procedures and Acceptance Criteria

API 610 includes detailed test procedures that must be followed to verify the performance and reliability of pumps. Acceptance criteria establish stringent standards that pumps must meet to comply with the standard.

API 610 specifications are critical to the petrochemical, oil, and gas industries as they guarantee the highest standards of reliability, efficiency, and safety. By complying with these standards, manufacturers and users can have confidence that API 610 pumps are suitable for even the most demanding applications.

ADVICE AND SALES

THE BEST POSSIBLE SOLUTION FOR YOUR APPLICATION

There are many different types of pumps and just as many applications, such as a submersible, circulation or well pump. Due to this diversity of pumps, it is wise to be well informed about what type of pump is required before you purchase one or have it overhauled. The IPG team with various pump experts can always advise you on the best possible solution for your application and can also support you with the purchase and installation of the pump.

IPG has strong relationships with various pump manufacturers and can therefore give you good advice in purchasing many types and brands of pumps. For example, the Industrial Pump Group is the Dutch importer of SAER and official dealer of Lowara, Grundfos and Seepex, among others.

SUSTAINABLE AND EFFICIENT

HAVE YOUR PUMP OVERHAULED