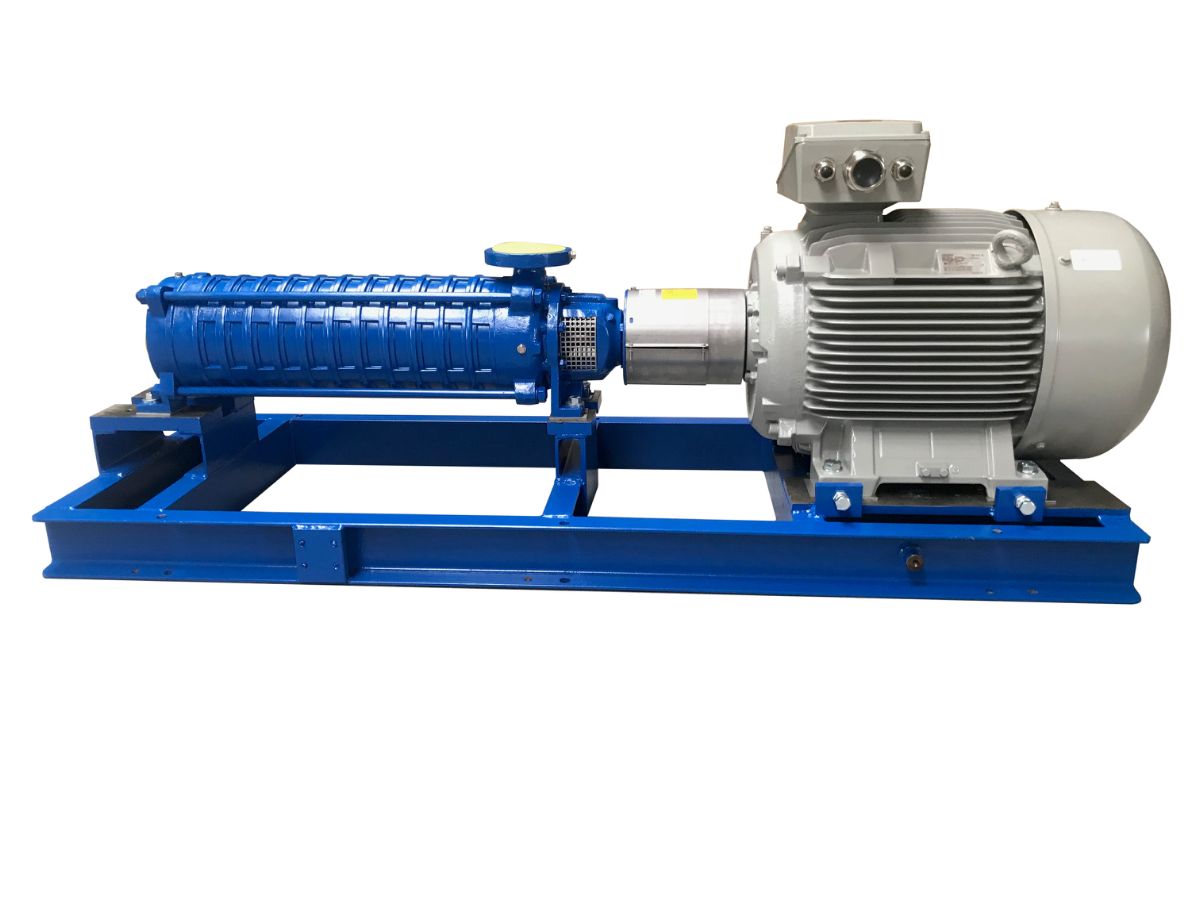

Multistage pumps

Multistage pumps are pumps that consist of multiple impellers and diffusers, making them capable of pumping water at higher pressures than single stage pumps.

Our customers rate us 8,6  based on 136 reviews

based on 136 reviews

optimal performance in your system

Multistage pumps

The multistage centrifugal pump consists of several stages with a centrifugal impeller and diffuser. The number of stages and motor speed determine the duty point of this type of pump used in high pressure applications.

The stages are interconnected with the first stage feeding the next and so on, increasing the pressure with each stage. The most commonly used version is the version in which the pump shaft is mounted using ball bearings in a bearing bracket outside the liquid section of the pump. Between the impeller and the bearing, the shaft seal ensures a liquid and airtight passage of the shaft into the pump housing.

The pump can be installed horizontally or vertically. In addition, various material options are available for both the impeller package and the seals. As with any pump, the system parameters determine which pump is best used in your system: flow rate and composition of the medium are some of the requirements for making a good selection and we can assist you with advice and action.

Versions of vertical multistage pumps

-

Low NPSH multistage pumps

- Immersion multistage pump for coolant or cutting oil

- Standard vertical and horizontal multistage pumps

- Multistage pumps and booster pumps for high temperature

- Condensate pumps, deep well pumps and boiler feed pumps

Horizontal and vertical booster pumps

All pumps are available in horizontal and vertical multistage pumps. Depending on the desired construction, we adapt the entire pump. We can place the standard pump vertically by supplying special pump supports.

Low NPSH or high temperature

The pumps we supply can be specially adapted to higher temperatures. We can also have the pumps designed for very low NPSHa values. We achieve this by using special circulation covers and impellers or by placing a special inducer in the suction of the pump. We can therefore guarantee a cavitation-free booster pump or multi-stage pump for, for example, condensate systems, boiler coding systems and deep well systems.

Advantages of a multistage pump

- Creates high pressure, which makes it suitable for heavy applications

- Suitable for various drives

- Available in various materials and with different seals, for every application

- Low maintenance

Our clients

Outstanding and accessible customer support at every touch point!

Deployment is perfect and very service-oriented. Both by phone, during planned realisation and unplanned breakdowns.

Project leader RGR at waste contractor in the Netherlands.

Rating: ⭐⭐⭐⭐ 4/5

Excellent experience with IPG: professionalism, quality and proactive problem solving!

As a work planner, I experience IPG as very professional. They strive for quality, think about improvements and fix breakdowns quickly to minimize downtime.

Work Planner at a water authority.

Rating: ⭐⭐⭐⭐⭐ 5/5

A reliable partner with outstanding service and customer-oriented advice!

I experience IPG as a very good partner, a company that values service, and thinks and advises with the customers.

Technical Service Work Planner at waste management company in the Netherlands.

Rating: ⭐⭐⭐⭐⭐ 5/5

Without obligation

Contact us

ADVICE AND SALES

THE BEST POSSIBLE SOLUTION FOR YOUR APPLICATION

There are many different types of pumps and just as many applications, such as a submersible, circulation or well pump. Due to this diversity of pumps, it is wise to be well informed about what type of pump is required before you purchase one or have it overhauled. The IPG team with various pump experts can always advise you on the best possible solution for your application and can also support you with the purchase and installation of the pump.

IPG has strong relationships with various pump manufacturers and can therefore give you good advice in purchasing many types and brands of pumps. For example, the Industrial Pump Group is the Dutch importer of SAER and official dealer of Lowara, Grundfos and Seepex, among others.

Multistage pumps

How do they work?

Basically, the pumping principle of a multi-stage pump is the same as a single impeller centrifugal pump. The difference is in the discharge or pressure side of this, which takes place directly at the discharge flange in a single-stage pump. In a multistage pump, this output goes to the suction of the next impeller. This ensures that the pressure is increased.

If the impeller would generate a pressure of 2 bar at a certain capacity, a pump with five impellers can generate 5 x 2 bar. The pressure of this multistage pump will be 10 bar. However, there is a loss of pressure. With each successive impeller there will be a greater pressure drop.

Maintenance and overhaul

Despite the fact that a multistage pump has an average longer life, because the wear of the pump is distributed over all impellers present, it is important that pumps are regularly inspected and that sufficient maintenance is carried out.

Maintenance and overhaul is important for all pumps. Would you like advice or would you like to outsource the revision? Please contact the IPG revision team.