Canned motor pumps

Canned motor pumps are hermetically sealed and offer advantages such as efficiency, reliability and safety when pumping liquids.

Our customers rate us 8,6  based on 136 reviews

based on 136 reviews

Transporting Hazardous Liquids

Canned motor pumps

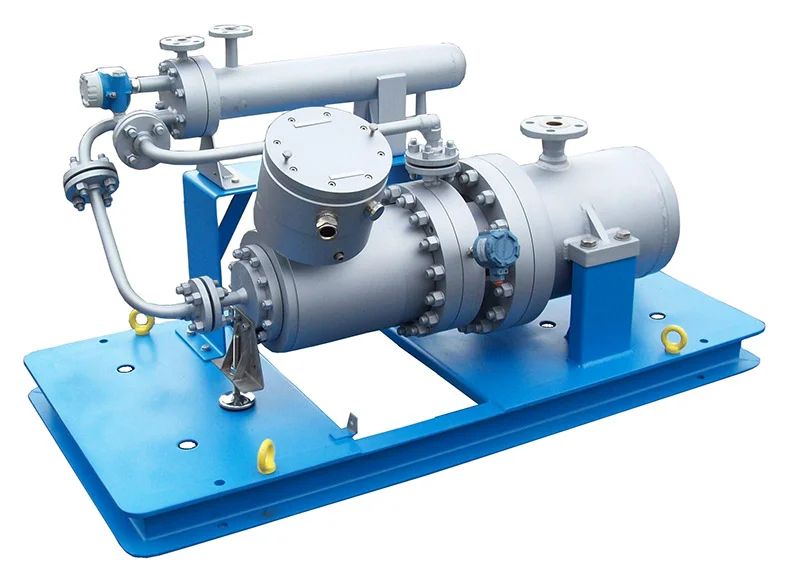

Canned motor pumps are a revolutionary solution for the safe and efficient transport of hazardous liquids, such as flammable, explosive and toxic substances. Unlike traditional pumps, which require a separate seal and shaft seal, the canned motor pump contains everything in one integrated system. This greatly reduces the risk of leakage and accidents.

Features Canned Motor Pumps

Canned motor pumps are a type of central shaft pump where the motor and pump are integrated in one housing. The motor is contained in so-called "cans" which also serve as a seal, eliminating the need for separate seals. This means there are fewer parts that can leak or fail, resulting in higher reliability and a lower risk of accidents.

Applications of Canned Motor Pumps Canned motor pumps are ideal for use in a variety of industries, including the petrochemical, chemical and pharmaceutical industries. They are also used for transporting hazardous materials in the shipping and nuclear industry.

Canned motor pumps offer several advantages, including higher reliability and safety due to the lack of separate seals. This makes them ideal for applications in a variety of industries, including the petrochemical, chemical and pharmaceutical industries. In addition, these pumps are often used in the shipping and nuclear industry, where the transport of hazardous materials is required.

Canned motor pumps are used in the petrochemical industry for pumping fuels and chemicals. Their compact housing makes them ideal for installations with limited space and they can be easily integrated into existing systems. In the pharmaceutical industry, these pumps are used for pumping sensitive liquids, where sterility and accuracy are essential.

Canned motor pumps are used in the shipping and nuclear industry to transport hazardous substances, such as radioactive waste and chemicals. Thanks to the hermetically sealed housing, they are safer and more reliable than traditional pumps with individual seals.

ADVICE AND SALES

THE BEST POSSIBLE SOLUTION FOR YOUR APPLICATION

There are many different types of pumps and just as many applications, such as a submersible, circulation or well pump. Due to this diversity of pumps, it is wise to be well informed about what type of pump is required before you purchase one or have it overhauled. The IPG team with various pump experts can always advise you on the best possible solution for your application and can also support you with the purchase and installation of the pump.

IPG has strong relationships with various pump manufacturers and can therefore give you good advice in purchasing many types and brands of pumps. For example, the Industrial Pump Group is the Dutch importer of SAER and official dealer of Lowara, Grundfos and Seepex, among others.

Strong in multiple areas

Advantages of Canned Motor Pumps

-

Safer than traditional pumps: The absence of separate seals and shaft seals reduces the risk of leakage and accidents.

-

More efficient and energy efficient: The integrated design ensures higher efficiency and lower energy consumption.

-

Longer service life: The canned motor pump is resistant to wear and corrosion, making the service life longer than that of traditional pumps.

-

Easy to maintain: The compact design makes it easy to carry out maintenance and repairs.