Centrifugal pumps

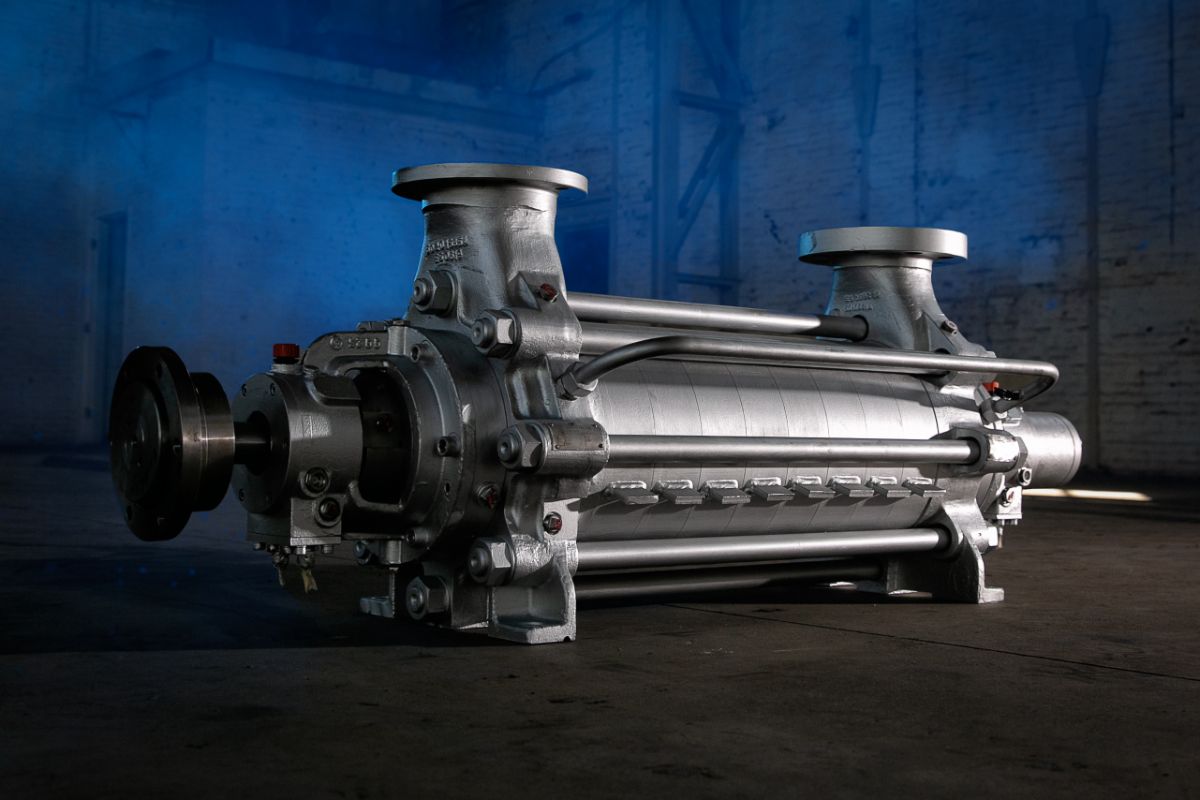

Centrifugal pumps are a widely used type of pump for moving liquids by means of a rotating impeller and centrifugal force.

Our customers rate us 8,6  based on 136 reviews

based on 136 reviews

Operation, applications and benefits

Most used pump in the industry

You can contact the Industrial Pump Group Nederland for many pumps, including centrifugal pumps. These pumps driven by an impeller or rotor are available in various types and materials and can therefore be used in various applications.

Examples of centrifugal pumps include: Magnetic pumps, monoblock pumps, submersible pumps and split case pumps. Chemical standard pumps can also be a centrifugal pump.

About the centrifugal pump

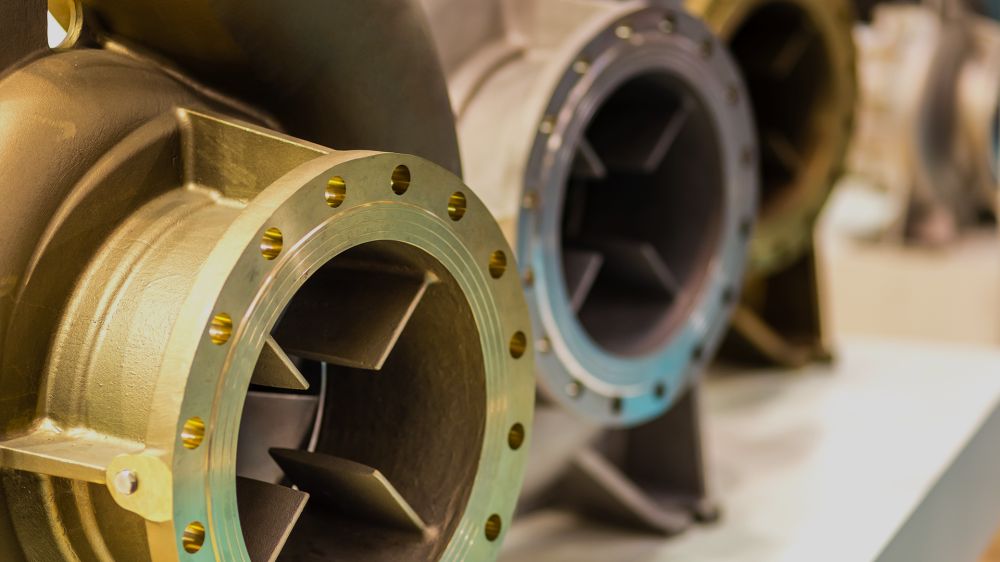

A centrifugal pump consists of a pump housing containing an impeller that rotates. In this principle, the liquid to be pumped is, as it were, thrown away by the revolving impeller, because of this throwing of the liquid to the outside, space is created on the inside (also called underpressure). New fluid can flow into this space, which ensures continuity of the pump and its operation.

Centrifugal pumps can be supplied as a separate pump (with and without motor) but also as a complete pump set.

In addition to the pump and motor itself, a pump set consists of a base plate and any other auxiliary facilities.

How does a centrifugal pump work?

The centrifugal pump, which includes a pump housing, impeller and electric motor, works with centrifugal force or centrifugal force, whereby the liquid is pumped. This force is generated by the impeller or rotor of the pump. This is located in the pump housing, which is equipped with a suction and discharge flange.

When the pump is started, the liquid in the pump starts to rotate with the impeller. The liquid experiences the action of the centrifugal force. It therefore flows into the pump housing at the outer circumference of the impeller and then, via the discharge opening, to the discharge pipe. However, these pumps cannot run dry (pumps without liquid), which are the advantages of a centrifugal pump, which you can read at the bottom of the page.

Outstanding and accessible customer support at every touch point!

Deployment is perfect and very service-oriented. Both by phone, during planned realisation and unplanned breakdowns.

Project leader RGR at waste contractor in the Netherlands.

Rating: ⭐⭐⭐⭐ 4/5

Excellent experience with IPG: professionalism, quality and proactive problem solving!

As a work planner, I experience IPG as very professional. They strive for quality, think about improvements and fix breakdowns quickly to minimize downtime.

Work Planner at a water authority.

Rating: ⭐⭐⭐⭐⭐ 5/5

A reliable partner with outstanding service and customer-oriented advice!

I experience IPG as a very good partner, a company that values service, and thinks and advises with the customers.

Technical Service Work Planner at waste management company in the Netherlands.

Rating: ⭐⭐⭐⭐⭐ 5/5

ADVICE AND SALES

THE BEST POSSIBLE SOLUTION FOR YOUR APPLICATION

There are many different types of pumps and just as many applications, such as a submersible, circulation or well pump. Due to this diversity of pumps, it is wise to be well informed about what type of pump is required before you purchase one or have it overhauled. The IPG team with various pump experts can always advise you on the best possible solution for your application and can also support you with the purchase and installation of the pump.

IPG has strong relationships with various pump manufacturers and can therefore give you good advice in purchasing many types and brands of pumps. For example, the Industrial Pump Group is the Dutch importer of SAER and official dealer of Lowara, Grundfos and Seepex, among others.

How does this problem arise?

Cavitation in centrifugal pumps

With centrifugal pumps, there is a risk of cavitation, which is the formation and destruction of water vapor bubbles in liquid water. When the pressure in the pump is lower than the vapor pressure of the liquid, cavitation occurs. The imploding vapor bubbles in the water cause (a lot of) noise and vibrations and then mechanical shocks occur. Cavitation leads to damage to various parts such as the impeller and the pump housing, which will obviously not benefit the life of the pump.

Cavitation can be prevented if the pump's inlet pressure (NPSHa) remains higher than the vapor pressure (NPSHr) of the pump. The NPSHa value must be at least 1 mWk higher than the NPSHr value. Once again it is very important that the pump that is selected is suitable for your application, would you like advice on this? Then please contact us.

PARTS AND REPAIR OF CENTRIFUGAL PUMPS

A centrifugal pump consists of not too many moving parts, so there are generally lower maintenance costs for this type of pump. The most wearing parts of a centrifugal pump are the impeller and the seals (also called the mechanical seal).

If you want to carry out maintenance on your (centrifugal) pump, it is important that this is done properly. With various pump experts, IPG has sufficient in-house knowledge to support you with the overhaul of your pumps.