Submersible pumps

Submersible pumps are used to draw water from wells, ponds and other reservoirs and are also used in the construction industry. They can also be used in case of flooding or sewage problems.

Our customers rate us 8,6  based on 136 reviews

based on 136 reviews

reliable and versatile solutions

Submersible pumps

Submersible pumps are powerful pumps that are submerged in water to pump it efficiently and effectively. They are widely used for pumping wastewater and sewage, but are also suitable for domestic use, such as pumping out a basement or swimming pool. Submersible pumps are available in different versions and powers, depending on the application and the type of water to be pumped. They are usually very reliable and can pump large volumes of water in a short time. When choosing a submersible pump, it is important to take into account factors such as the size of the volume of water to be pumped, the maximum head and the desired speed of pumping.

Why a submersible pump?

-

No problems with suction

- Produces little noise

- Simple installation

- Clogging free

Submersible pumps for clean and contaminated liquids

In addition to providing advice, Industrial Pump Group Nederland can also supply you with various submersible pumps: from pumps for clean liquids such as (drinking) water, industrial water and effluent to polluted liquids such as influent and faeces. The design of the pumps and impellers varies from fully closed impellers, semi-open impellers and fully open impellers to vortex impellers and single or multi-channel impellers.

When selecting the right fan, we take your application into account so that the most effective fan shape is used for maximum results. Whether it concerns clog-free operation or an installation for maximum pump efficiency. In addition, the composition of the medium can also lead to the need for special materials.

In the case of chemically contaminated water, the material to be used must be corrosion resistant and the choice will be stainless steel 316 or Duplex. If the medium is abrasive (wearing), a material alloy will be chosen that is wear-resistant, so that the service life of the pump will be correspondingly. A correct choice ensures trouble-free operation at the lowest possible energy costs.

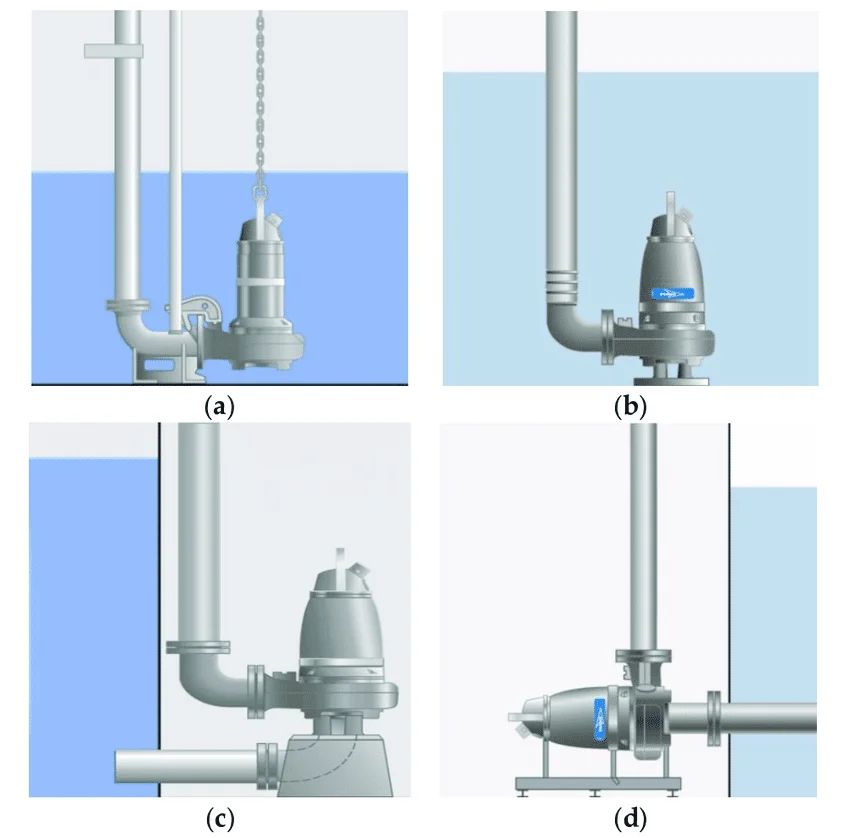

Submersible pump setup

Smaller variants can be placed directly on the surface. We provide industrial submersible pumps with a 'tripod' or a 'coupling foot bend'.

a. Submerged installation

b. portable installation

c. Vertical dry installation

d. Horizontal dry installation

Outstanding and accessible customer support at every touch point!

Deployment is perfect and very service-oriented. Both by phone, during planned realisation and unplanned breakdowns.

Project leader RGR at waste contractor in the Netherlands.

Rating: ⭐⭐⭐⭐ 4/5

Excellent experience with IPG: professionalism, quality and proactive problem solving!

As a work planner, I experience IPG as very professional. They strive for quality, think about improvements and fix breakdowns quickly to minimize downtime.

Work Planner at a water authority.

Rating: ⭐⭐⭐⭐⭐ 5/5

A reliable partner with outstanding service and customer-oriented advice!

I experience IPG as a very good partner, a company that values service, and thinks and advises with the customers.

Technical Service Work Planner at waste management company in the Netherlands.

Rating: ⭐⭐⭐⭐⭐ 5/5

ADVICE AND SALES

THE BEST POSSIBLE SOLUTION FOR YOUR APPLICATION

There are many different types of pumps and just as many applications, such as a submersible, circulation or well pump. Due to this diversity of pumps, it is wise to be well informed about what type of pump is required before you purchase one or have it overhauled. The IPG team with various pump experts can always advise you on the best possible solution for your application and can also support you with the purchase and installation of the pump.

IPG has strong relationships with various pump manufacturers and can therefore give you good advice in purchasing many types and brands of pumps. For example, the Industrial Pump Group is the Dutch importer of SAER and official dealer of Lowara, Grundfos and Seepex, among others.

More information

What is a submersible pump?

A submersible pump is a pump that, submerged in the medium to be pumped, is used to pump away clean or polluted water. The submersible pumps are one of the most commonly used pumps and the range is very large. It is therefore important to properly map out the selection criteria that your pump must meet. We list the most important things:

Is the medium to be pumped clean or polluted water? Does a percentage of sand or other solids have to be pumped?

What is the required capacity of your application: how many m3/hour or litres/sec must be pumped?

What is the head also called pressure: this is the maximum height in meters that the pump must be able to pump. If the pump is located in a well of 2 meters deep and the discharge point is 6 meters higher, you need a pump that must be able to pump at least 8 meters high

What is the length and diameter of the pressure pipe and is it known how many bends are installed.

How do you want to install and switch the pump. The pump can be switched automatically by means of a float switch, which has the additional advantage that the pump cannot run dry.

In terms of installation or set-up method, there are countless options, such as dry installation with a cooling jacket, free-standing on a stand ring on a rigid or flexible pressure pipe or conventional on a guide tube installation. We would like to advise you about all these options.

Submersible pump with cutting device

When the medium contains solid and long fiber materials (paper, straw, leaves) a pump with a cutting device can be used. The pumps are then fitted with a cutting device for the inlet flange (suction flange). This reduces all solid parts to pumpable parts.

Some dirty water pumps are fitted as standard with a cutting device on both sealing rings, at the front and rear of the impeller. With the open impellers, some pumps have a wear plate with standard cutting grooves, which ensure clog-free operation.

Clogging free

Our pumps are equipped with a cutting device for the inlet flange (suction flange). This reduces all solid parts to pumpable parts. Some dirty water pumps are fitted as standard with a cutting device on both sealing rings, at the front and rear of the impeller. With the open impellers, some pumps have a wear plate with standard cutting grooves, which ensure clog-free operation.

ATEX

The ATEX directive applies to all places where there is a risk of explosion. The directive has a broad field of application and, in addition to gas explosion, also includes dust explosion hazards. ATEX stands for ATmosphères EXplosives.

ATEX pump certification applies to the entire pump unit, so to both the ATEX submersible pump and the ATEX motor. The submersible pumps can be supplied with ATEX certification.

Depending on the zone in which the pumps are installed, we can inform you about how to manage the risk of explosion.

For the elaboration of an ATEX application, we will always ask you for which zone the pump must be suitable and which medium will be pumped.

Applications

A submersible pump is a versatile pump, when the pump is equipped with a float, it is also immediately protected against the pump running dry. A submersible pump is widely used as construction or sewage pumps. This is because the pumps (depending on the type of pump) are generally wear-resistant and clog-free. The submersible pump is also often used for domestic use when emptying a cellar. This is because the pumps are compact.

Construction and sewage pump

Submersible pumps come in many shapes and sizes, therefore also for various applications. In construction, for example, a robust submersible pump with a larger free passage is often used. These pumps can often pump sand or even sludge. A good example of these types of pumps are those from Grindex and Flygt.

Flygt also makes various submersible pumps that are suitable for an application where sewage must be pumped.

Domestic use

In some cases, submersible pumps are used for domestic use, which may be for pumping out a cellar, for example. When the pump has to start at a specific water level, a float can be used. Lowara and Ebara, among others, sell these types of submersible pumps.

High efficiency

The pumps supplied by us all have a particularly high efficiency, so that the energy consumption remains low. Our high-efficiency submersible motors are even suitable for higher temperatures.