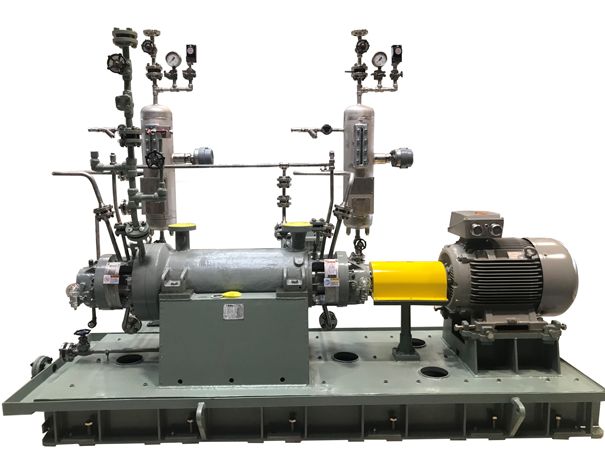

Boilerfeed pumps

A boiler feed pump is a type of pump that transports water from a storage tank to a boiler. It provides a constant flow of water to the water heater to ensure efficient operation. These pumps often have a high pressure capacity and are specially designed to operate at high temperatures and pressures.

Our customers rate us 8,6  based on 136 reviews

based on 136 reviews

Everything you need to know

Boiler feed pumps

Boiler feed pumps play an essential role in the functioning of a boiler installation. They are centrifugal pumps that are used to pump water from low pressure to a higher pressure, in order to feed the boiler with water. This process is critical to the efficient operation of the water heater and extending the life of the equipment.

Boiler feed pumps are indispensable in the industry and it is important to select and maintain the right pump for the efficient and safe operation of the boiler installation.

The key to efficient boiler operation

There are several types of boiler feed pumps available, including single-stage and multi-stage pumps. Single stage pumps are used for low pressure applications, while multistage pumps are required for higher pressures. It is important to choose the right pump based on the desired pressure increase and flow rate.

An important aspect of using boiler feed pumps is pump maintenance and performance monitoring. Regular maintenance is essential to ensure that the pump functions properly and to prevent unnecessary wear. Performance monitoring can be performed using techniques such as vibration analysis, thermography and ultrasonic testing.

There are several industries where boiler feed pumps are used, including the food industry, the pharmaceutical industry and the power generation sector. In these industries, safety and efficiency are of great importance and boiler feed pumps are indispensable for the proper functioning of the boilers.

The advantages of a boiler feed pump

Boiler feed pumps offer several advantages for the efficient operation of boilers. First, they help extend the life of the equipment by feeding the water heater with water of the correct pressure and temperature. This prevents overheating and water damage to the equipment and reduces the risk of unexpected outages.

Another advantage of using boiler feed pumps is that it increases the efficiency of the boiler. This is because the pumps feed water at the right pressure and temperature to the water heater, which means the water heater uses less energy to get the water to the right temperature. This not only saves energy, but also reduces harmful emissions and lowers costs.

Boiler feed pumps are also a safety measure. By regularly maintaining and monitoring the performance of the pumps, the risk of malfunctions and unexpected breakdowns is minimized. This is especially important in industries where boiler feed pumps are used, where safety and efficiency are paramount.

Our clients

IPG' Robert: essential support for water treatment projects.

As a project manager, I appreciate Robert's expert support from IPG, his commitment to water treatment projects and quick response to breakdowns are invaluable. With Robert, we have a pump technology expert and reliable advisor for our operations.

Project Manager at a water treatment plant.

Rating: ⭐⭐⭐⭐⭐ 5/5

Reliable and proactive service from IPG!

As head of TD, I appreciate the reliability of IPG's brand independence and proactive approach. Their prompt service is crucial in our industry where every minute of downtime counts.

Head of Technical Services at a chemical plant.

Rating: ⭐⭐⭐⭐ 4/5

IPG is an indispensable partner for production efficiency!

As a production manager, I appreciate IPG as an indispensable partner for efficiency and uptime. Their expert team helped us with the jusite pumps and sevice for production consistency.

Project Manager at a paper mill.

Rating: ⭐⭐⭐⭐⭐ 5/5

Without obligation

Contact us

ADVICE AND SALES

THE BEST POSSIBLE SOLUTION FOR YOUR APPLICATION

There are many different types of pumps and just as many applications, such as a submersible, circulation or well pump. Due to this diversity of pumps, it is wise to be well informed about what type of pump is required before you purchase one or have it overhauled. The IPG team with various pump experts can always advise you on the best possible solution for your application and can also support you with the purchase and installation of the pump.

IPG has strong relationships with various pump manufacturers and can therefore give you good advice in purchasing many types and brands of pumps. For example, the Industrial Pump Group is the Dutch importer of SAER and official dealer of Lowara, Grundfos and Seepex, among others.

A crucial role in energy efficiency and sustainability

Boiler feed pumps in heat recovery systems

Boiler feed pumps play a vital role in the heat recovery system as they help to pump the hot water that comes out of the boiler and use it efficiently in other parts of the production process. For example, the hot water can be used to heat other equipment, reducing the plant's energy consumption and saving costs.

To keep the hot water at the right pressure and to move it efficiently, a boiler feed pump is used. These pumps are designed to pump water at high temperatures and pressures, making them ideal for moving hot water from the boiler to other parts of the process.

In the heat recovery system, the hot water is first passed through the boiler feed pump before going to the heat exchanger. The heat exchanger uses the hot water to heat other equipment, reducing the plant's energy consumption. After leaving the heat exchanger, the cooled water returns to the boiler, where it is heated again and the process is repeated.

The use of a boiler feed pump in the heat recovery system allows hot water to be maintained at the right pressure and used efficiently, improving production efficiency and plant energy efficiency. In addition, the use of such a system can contribute to the reduction of the plant's carbon footprint, as less energy is required to heat the equipment.

Sustainable and efficient

Have your pump overhauled