API pumps

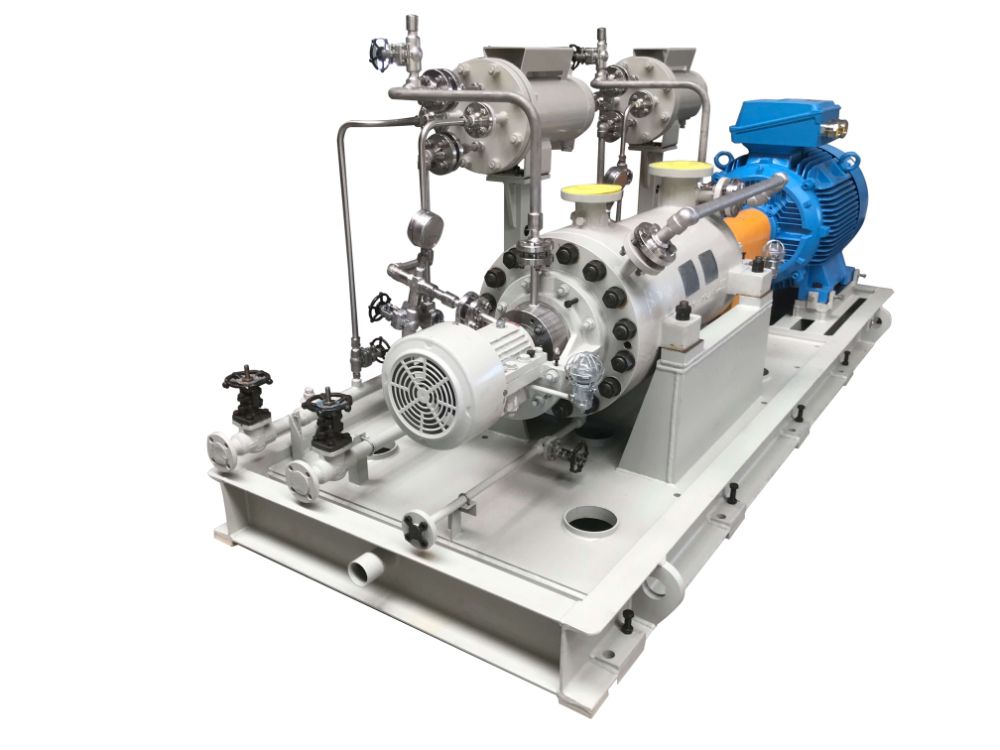

API pumps are pumps that meet the standards of the American Petroleum Institute (API). They are designed to meet the stringent requirements of the oil and gas industry and provide reliability, safety and efficiency.

Our customers rate us 8,6  based on 136 reviews

based on 136 reviews

API Specifications

IMPORTANT IN THE OIL AND GAS INDUSTRY

API specifications are critical for pumps in the oil and gas industry, where reliability, safety and performance are paramount. The American Petroleum Institute (API) has established a set of specifications that pumps must meet in order to be suitable for use in the oil and gas industry. These specifications include the construction, materials, dimensions, performance criteria, testing requirements and certifications of the pump.

By meeting API specifications, pumps can guarantee high reliability and safety, minimizing breakdowns and safety risks. In addition, adherence to API specifications helps to optimize pump performance and efficiency, reducing operating costs and extending pump life.

API standards contribute to reliable performance

API (American Petroleum Institute), an organization that sets standards and guidelines for the oil and gas industry. The API standards are essential to the design, manufacture and performance of pumps in the oil and gas industry. The API standards are designed to guarantee the quality and reliability of pumps and to ensure that they meet the specific needs of the industry.

Some examples of API standards that apply to pumps are:

- API 610: This standard sets requirements for the design and performance characteristics of centrifugal pumps for the oil, gas and petrochemical industries. The standard includes requirements for materials, dimensions, performance, testing and inspections.

- API 674: This standard sets requirements for the design and performance characteristics of plunger pumps for the oil, gas and petrochemical industries. The standard includes requirements for materials, dimensions, performance, testing and inspections.

- API 675: This standard sets requirements for the design and performance characteristics of dosing pumps for the oil, gas and petrochemical industries. The standard includes requirements for materials, dimensions, performance, testing and inspections.

API standards are critical to pump performance. Compliance with these standards guarantees that the pumps are reliable and durable. This is of great importance in the oil and gas industry, where pumps are often exposed to harsh conditions and high pressures.

Failure to meet API standards can lead to various problems such as leakage, corrosion, reduced performance and even pump failure. This can lead to plant downtime, higher maintenance costs and even hazardous situations for personnel and the environment.

Therefore, the pumps must be inspected and tested regularly to verify that they meet API standards. These inspections and tests must be performed by qualified and experienced personnel to ensure that the results are reliable.

It is important to mention that the API standards are not mandatory regulations. However, because the API standards are commonly used in the oil and gas industry, they are considered an industry standard. Many companies choose to purchase pumps that meet API standards to ensure they are reliable and meet industry requirements.

Our clients

Without obligation

Contact us

ADVICE AND SALES

THE BEST POSSIBLE SOLUTION FOR YOUR APPLICATION

There are many different types of pumps and just as many applications, such as a submersible, circulation or well pump. Due to this diversity of pumps, it is wise to be well informed about what type of pump is required before you purchase one or have it overhauled. The IPG team with various pump experts can always advise you on the best possible solution for your application and can also support you with the purchase and installation of the pump.

IPG has strong relationships with various pump manufacturers and can therefore give you good advice in purchasing many types and brands of pumps. For example, the Industrial Pump Group is the Dutch importer of SAER and official dealer of Lowara, Grundfos and Seepex, among others.

API pumps of various brands

IPG supplies various brands

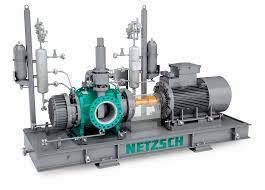

There are several pump brands that sell API pumps, each with their own unique features and specialties. Some examples of these brands are discussed below, namely Goulds, Handol, Netzsch and Sulzer.

Goulds is a well-known manufacturer of API pumps. The company offers a wide range of pumps that meet API standards, including centrifugal pumps, plunger pumps and dosing pumps. Goulds is best known for its XHD pump, which is designed for use in harsh conditions. This pump has a modular design, which means that it is possible to replace various components without having to replace the entire pump.

Handol is another manufacturer of API pumps. The company mainly focuses on dosing pumps and has a wide range of pumps that comply with the API 675 standard. Handol is known for its accurate and reliable dosing pumps suitable for use in the oil, gas and petrochemical industries.

Netzsch is a German company focused on the design and manufacture of pumps and other equipment for the oil and gas industry. The company offers a wide range of pumps that meet API standards, including eccentric worm pumps and lobe pumps. These pumps are mainly used for pumping viscous liquids and solids.

Sulzer is a Swiss company that produces a wide range of pumps for different applications, including pumps that meet API standards. Sulzer has extensive experience in the oil and gas industry and offers various pump types, such as centrifugal pumps and plunger pumps. Sulzer pumps are commonly used in oil and gas extraction, refineries and petrochemical plants.

SUSTAINABLE AND EFFICIENT

Have your pump overhauled