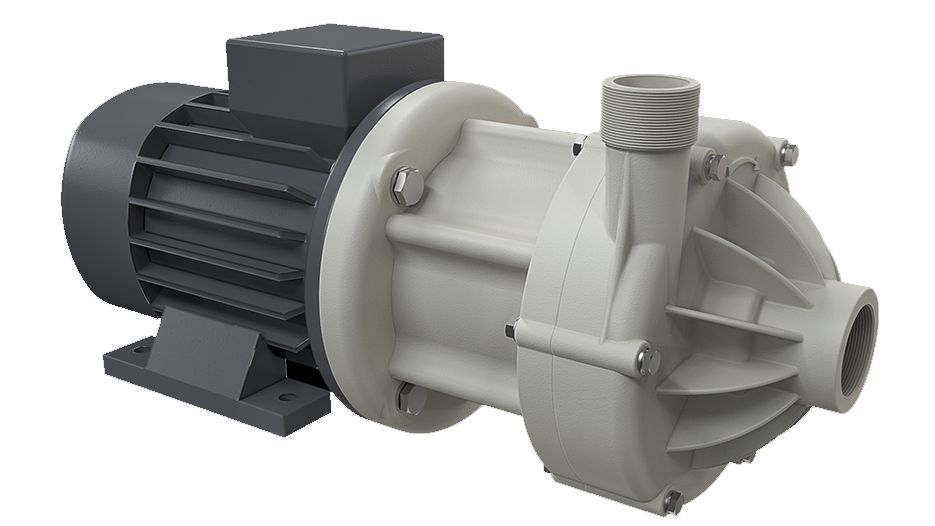

Thermoplastic pumps

Thermoplastic pumps are widely used in industry due to their corrosion resistance and chemical inertness, making them suitable for a wide range of applications.

Our customers rate us 8,6  based on 136 reviews

based on 136 reviews

Benefits and Applications

Thermoplastic pumps in industry

Thermoplastic pumps are designed for corrosive and abrasive industrial applications. The pumps are made of chemically resistant materials such as polypropylene, PVC, PVDF, Teflon and other polymers. This makes them resistant to corrosion, heat and chemical attacks. In addition, they are lightweight, easy to install and require little maintenance. Plastic pumps are often used in the chemical, pharmaceutical and food industries, as well as in the water treatment and electroplating industries. Thanks to their reliability, efficiency and durability, plastic pumps are an important component in many industrial applications.

Everything you need to know about industrial thermoplastic pumps

Industrial thermoplastic pumps are designed for applications where corrosion and wear play a major role. They are made of durable and chemically resistant materials, such as polypropylene, PVC, PVDF, Teflon and other polymers. These materials offer excellent resistance to corrosion, high temperatures and chemical attacks. In addition, thermoplastic pumps are lightweight, easy to install and require little maintenance.

Thermoplastic pumps are widely used in chemical, pharmaceutical, food industry, as well as in water treatment, electroplating industry and other industries where corrosive liquids are pumped. In these applications, plastic pumps provide reliable, efficient and durable performance. However, it is important to choose the right plastic pump for the specific application and to maintain the pump regularly to optimize its life and performance.

Maintenance

Regular maintenance is required to optimize the performance of plastic pumps. It is important to inspect the pump, clean it and repair any wear or damage. By carrying out regular maintenance, the life of the pump can be extended and malfunctions can be prevented.

ADVICE AND SALES

THE BEST POSSIBLE SOLUTION FOR YOUR APPLICATION

There are many different types of pumps and just as many applications, such as a submersible, circulation or well pump. Due to this diversity of pumps, it is wise to be well informed about what type of pump is required before you purchase one or have it overhauled. The IPG team with various pump experts can always advise you on the best possible solution for your application and can also support you with the purchase and installation of the pump.

IPG has strong relationships with various pump manufacturers and can therefore give you good advice in purchasing many types and brands of pumps. For example, the Industrial Pump Group is the Dutch importer of SAER and official dealer of Lowara, Grundfos and Seepex, among others.

The contribution of thermoplastic pumps

Efficiency, sustainability and safety

Industrial plastic pumps play an important role in improving the efficiency, sustainability and safety of industrial processes. These pumps are designed for applications involving the handling of corrosive liquids and are made of chemically resistant materials such as polypropylene, PVC, PVDF and Teflon. The use of these materials allows plastic pumps to provide a long service life, even in the most challenging conditions.

Plastic pumps are widely used in the chemical, pharmaceutical and food industries, as well as in water treatment, electroplating and other industries where corrosive liquids are pumped. In these applications, plastic pumps provide reliable, efficient and durable performance. By reducing downtime and minimizing maintenance costs, plastic pumps can also improve the efficiency of industrial processes.

In addition to improving efficiency, plastic pumps can also contribute to the sustainability and safety of industrial processes. By reducing environmental impact and minimizing the risk of leaks and equipment damage, plastic pumps can provide a safer and more sustainable working environment.

SUSTAINABLE AND EFFICIENT

Have your pump overhauled