Operation of Centrifugal Pumps

the most used pumps in the industry

HOW DO THESE PUMPS WORK?

The operation of a centrifugal pump is quite simple. The centrifugal pump is not self-priming, which means that this type of pump does not suck in the liquids to be pumped and therefore cannot suck up from a lower well or well.

- Often compact for the output that the pump delivers

- Few moving parts resulting in relatively low maintenance costs

- Even volume flow

The principle of the centrifugal pump

The operation of a centrifugal pump is a fairly simple principle, the liquid is, as it were, 'thrown away'. The impeller rotates, so that the medium contained in the vanes of the impeller is flung away and moves forward through it. You understand: there has to be something to be thrown away and therefore to be pumped. Without medium, the pump will not work and will even wear out. Before using a centrifugal pump, the pump must first be filled with the medium to be pumped.

With a centrifugal pump it is possible to achieve a relatively high pressure, this pressure and therefore the difference between the discharge and suction pressure of the pump is called head and often expressed in meters of liquid column (mvc) or more commonly: bar. 1 bar = 10 mvc. For example, if a pump has a head of 10 meters of liquid column, this pump will be able to “lift” the liquid 10 meters in relation to the suction side. In this case a liquid column of 10 meters, this is expressed in 1 bar.

The exact operation centrifugal pump

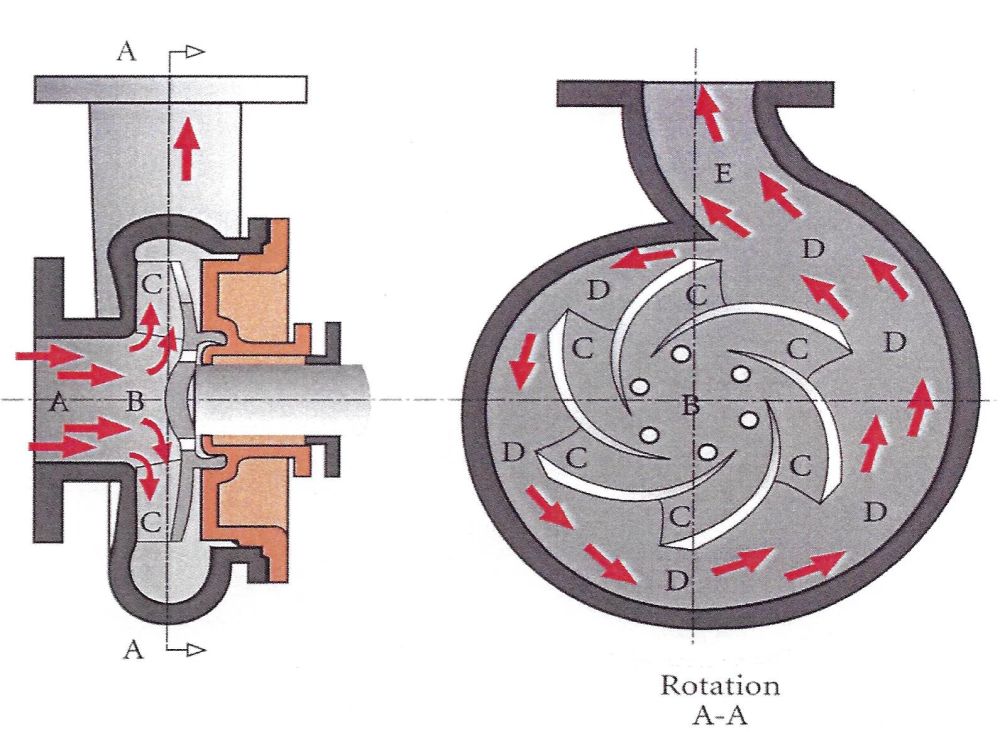

Below/above we offer you a schematic overview of the operation of a centrifugal pump.

The suction line carries the liquid in at A to the eye of the impeller (B). The impeller vanes around this accelerate the fluids in the direction of rotation of the impeller. Due to the energy and speed of this, the restriction of the pump housing converts this into pressure.

The liquid will always enter through the suction side and then through the vanes on the impeller and be thrown out through the pressure side under the influence of these centrifugal forces. Because a centrifugal pump is not self-priming, the pump housing must already be filled before the pump starts up.

ADVICE AND SALES

THE BEST POSSIBLE SOLUTION FOR YOUR APPLICATION

There are many different types of pumps and just as many applications, such as a submersible, circulation or well pump. Due to this diversity of pumps, it is wise to be well informed about what type of pump is required before you purchase one or have it overhauled. The IPG team with various pump experts can always advise you on the best possible solution for your application and can also support you with the purchase and installation of the pump.

IPG has strong relationships with various pump manufacturers and can therefore give you good advice in purchasing many types and brands of pumps. For example, the Industrial Pump Group is the Dutch importer of SAER and official dealer of Lowara, Grundfos and Seepex, among others.

Various manufacturers

View the brands of centrifugal pumps

Many pump brands produce centrifugal pumps, for advice on which centrifugal pump can best be used for your application, it is best to contact the Industrial Pump Group. IPG has years of experience in selecting, advising and overhauling (centrifugal) pumps and has also built up a good relationship with major pump manufacturers over the years. This way we can give you the best brand-independent advice for choosing a centrifugal pump.

IPG supplies, among others, the following brands of (centrifugal) pumps:

Type centrifugal pumps

Although the principle of a centrifugal pump is the same for every centrifugal pump, whereby the water enters the pump via the suction side and leaves the pump via the impeller via the pressure side, there are various types of pumps available with a centrifugal pump principle. Some examples are:

Magnetic pumps

- Used for pumping environmentally hazardous, but otherwise clean liquids

- Leak-proof

- Can be powered by any standard drive

Single stage monoblock pumps

- Often used in simple applications

- Small installation space

- Easy maintenance

Vertical flange pumps

- Ideal when space is a problem

- Compact

- Visual inspection easy

Split case pumps

- For large capacities and/or pressures

- Suitable for high speeds

- Solid shaft/bearing construction for heavy loads and large capacities