Pharmaceutical industry

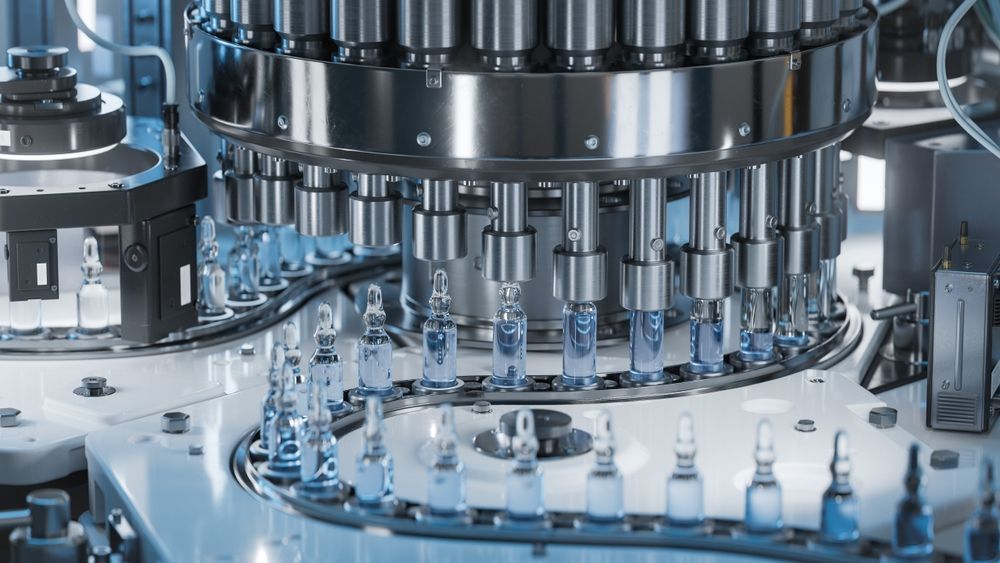

Pumps in the pharmaceutical industry are essential for accurate dosing and transport of liquids. They are used for various processes, such as filtration, chromatography and bioreactors. Moreover, they have to meet strict hygiene and safety standards.

- Centrifugal pumps

- Worm pumps

- Diaphragm pumps

- Netzsch pumps

- Debem pumps

Our customers rate us 8,6  based on 136 reviews

based on 136 reviews

hygienic pumps

Pumps for pharmaceutical applications

Most hygienic pumps are used in the pharmaceutical industry because they are subject to very strict hygiene and quality standards. Manufacturers of pharmaceutical pumps face very strict hygiene and quality requirements for components - especially in terms of maintenance and cleaning. One such body that enforces standards in the US is the FDA (Food and Drug Administration), the FDA sets standards for pump materials, the quality of lubricants used for pump lubrication and more. In Europe, requirements are set by the body EHEDG.

Strict compliance with hygiene standards

Pharmaceutical pumps adhere to stringent FDA and EHEDG standards, ensuring the highest levels of hygiene and quality in drug production.

Prevents contamination

Designed to minimize contamination risks, these pumps help maintain the purity and therapeutic effectiveness of medicines.

Critical for patient safety

Used in hospitals and medical institutions, these pumps ensure accurate dosing and prevent health risks, safeguarding patient safety.

Essential for regulatory compliance

Compliant with government regulations, these pumps ensure that pharmaceutical production meets strict hygiene and quality requirements.

Why hygiene is crucial in pharmaceutical pumps

Hygiene is an important factor in the pharmaceutical industry and it plays a crucial role in the production and processing of medicines. Pharmaceutical pumps are an important part of this process and it is therefore very important that these pumps are designed and used hygienically. This is because poor hygiene can lead not only to contamination of medicines, but also to health problems for patients.

There are several reasons why hygiene is so important in pharmaceutical pumps. First, medicines need to be pure to maintain their therapeutic effect. Contamination of medicines can lead to less effective treatments or even harmful reactions in the patient. Hygiene is therefore very important to ensure that medicines are administered to patients in the right concentration and quality.

Second, pharmaceutical pumps can be a source of contamination as they come into direct contact with the drugs. If the pump is not used hygienically, it can become contaminated with bacteria, viruses and other harmful substances. This can lead to contamination of the drugs and hence health problems for the patient.

Another reason why hygiene is important with pharmaceutical pumps is that these pumps are often in use in hospitals and other medical institutions. Here, they are used to care for patients with serious conditions, where incorrect dosing of medicines can be life-threatening. Therefore, it is necessary to ensure that pharmaceutical pumps are always used hygienically.

Finally, it is also important to mention that hygiene in the pharmaceutical industry is a requirement imposed by the government. There are strict guidelines and regulations to ensure hygiene in the production and processing of medicines. This is necessary to ensure that high-quality medicines are administered to patients, giving them a better chance of being cured.

Advice and sales

De best mogelijke oplossing voor uw applicatie

Er zijn veel verschillende soorten pompen en evenzovele applicaties, denk bijvoorbeeld aan een dompel-, circulatie- of bronpomp. Door deze diversiteit van pompen is het verstandig om goed geïnformeerd te zijn over wat voor type pomp benodigd is voordat u er een aanschaft of laat reviseren. Het IPG team met diverse pompexperts kunt u altijd adviseren over de best mogelijke oplossing voor uw applicatie en kunt u tevens hierbij ondersteunen met de aanschaf en installatie van de pomp.

IPG heeft met diverse pompfabrikanten sterke relaties en kunt u hierom goed adviseren in het aanschaffen van vele type en merken pompen. Zo is de Industrial Pump Group de Nederlandse importeur van SAER en officieel dealer van o.a. Lowara, Grundfos en Seepex.

Eisen van een Farmaceutische pomp

- Moet geschikt zijn voor steriel en hygiënisch gebruik

- Gemaakt van chemisch bestendig materiaal

- Kan zeer viskeuze vloeistoffen verwerken

- Onderhoudsvriendelijk

Type pompen gebruikt in de farmaceutische industrie

- Centrifugaalpompen

- Lobbenpompen

- Membraanpompen

- Wormpompen

Niet zeker welke pomp benodigd is?

Wij zijn er om te helpen!

De Industrial Pump Group is de specialist als het gaat om pomptoepassingen, wij hebben meer dan 30 jaar ervaring in de branche. IPG is officieel dealer en heeft sterke banden met diverse fabrikanten van industriële pompen, wij kunnen de juiste industriële pomp leveren voor elke toepassing in de farmaceutische industrie, maar ook bieden wij gespecialiseerd onderhoud diensten voor de bestaande pompen.

Voor vragen over de pomptoepassingen in de farmaceutische industrie of een offerte kunt u vrijblijvend contact opnemen met IPG via: (0251) 222 566 of info@industrialpumps.nl.